Over 8,000 products in-stock! & FREE 2-Day shipping on all web orders!* Learn More FREE T-Shirt with orders $250+ Details

Over 8,000 products in-stock! & FREE 2-Day shipping on all web orders!* Learn More FREE T-Shirt with orders $250+ Details Notice: Products may be subject to a surcharge added during checkout. Learn More

- Products

- Solutions

- Resources

-

Support

- Technical Support

- Service & Returns

- Trade Shows & Events

- Company Information

- Contacts & Locations

- Contact Us

- Corporate Headquarters

- Worldwide Sales & Service

- Supplier Information

- Supplier Code of Conduct

- Terms & Conditions of Purchase

-

Contact

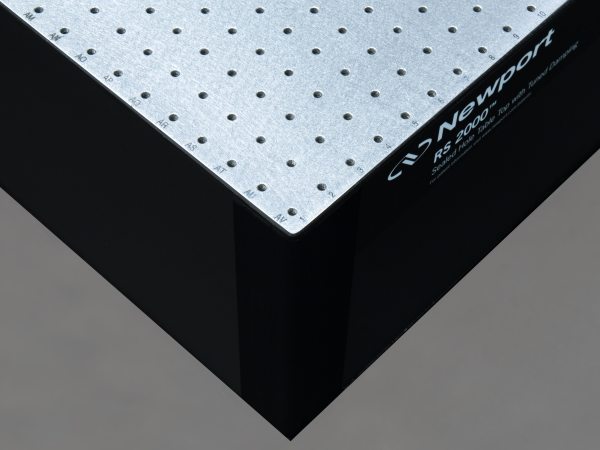

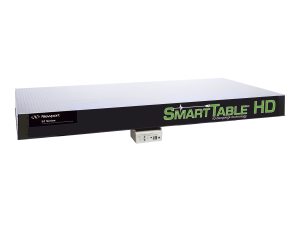

Ultra-High Velocity

Ultra-High Velocity