Safety hazards related to laser usage are generally separated into radiation hazards (associated with interaction with the laser beam itself) and electrical hazards (those associated with the electronic equipment used to operate the laser). Since radiation hazards are unique to laser operation, those will be discussed here. While high-power lasers do have the capability of inflicting burns on the skin, the eye is the part of the body most vulnerable to radiation hazards. Eye injuries generally have more dire consequences, e.g., partial loss of vision, and can occur at lower laser powers. These low thresholds exist because the lens of the eye can focus collimated laser light to a tiny spot on the retina leading to much higher intensities than experienced at the pupil. To quantify how much exposure to laser light is hazardous, maximum permissible exposure (MPE) limits are tabulated in terms of the allowable exposure time for a given intensity. The MPE is dependent on the specific laser characteristics, e.g., wavelength, power, beam size, repetition rate, as well as the spectral transmission of the eye itself.

Engineering

Controls |

Procedural

Controls |

Personal Protective

Equipment |

| Protective housing and service panel |

Laser safety officer |

Eyewear |

| Door interlocks and remote control connector |

Standard operating procedures |

Clothing |

| Beam attenuators and beam shutters |

Limitations on use by class |

Gloves |

| Key switch or padlock |

Entry limitations for visitors |

|

| Warning lights, emission indicators |

Education and training |

|

| Beam enclosure |

Maintenance and service manuals |

|

| Controlled beam path |

Marking of protective devices |

|

| Laser controlled area |

Warning signs and labels |

|

| Beam stops |

|

|

Table 2. Control measures for Class 3b and Class 4 lasers.

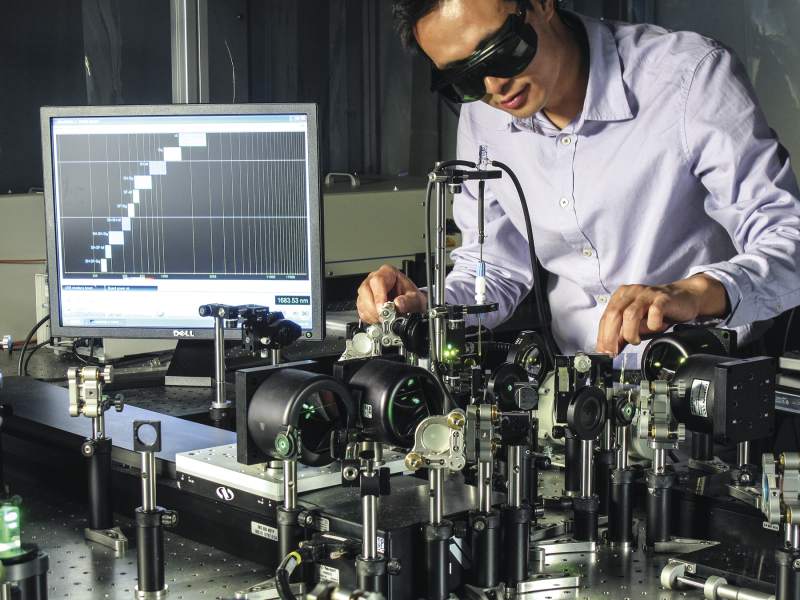

The potential hazards associated with laser usage coupled with the ubiquity of laser applications require that laser safety control measures must be implemented in workplace and educational environments. These control measures are summarized in Table 2. Engineering controls are specifically designed to restrict or reduce exposure to laser radiation. Obviously one should never look directly into a laser light source or at scattered laser light from any reflective surface, but misalignments leading to accidental reflections can and do occur during normal operation. Such controls include ensuring that the laser and associated optical components are situated below eye level, proper enclosures are provided for the beam, all unused beams are properly terminated with beam dumps or stops, and that laser interlocks are utilized. Procedural controls help guarantee that personnel involved with the use of hazardous laser systems are properly trained and familiar with safety protocols. Finally, the use of personal protection equipment (PPE) is critical since it functions as the final safeguard against injury. Proper clothing and gloves can ensure minimal skin exposure to laser radiation but protective eyewear or laser safety glasses or goggles are the most important type of PPE. Laser goggles should have the appropriate attenuation factor, e.g., transmission reduction, to ensure that the MPE is never exceeded given the maximum output power of the laser being used.

The large intensities associated with laser output can lead to laser-induced damage of optical components. These can include components within a laser cavity itself, e.g., laser rod, resonator mirrors, modulators, the NLO crystals used for frequency conversion, any of the optical components that are used in optical systems, or power and energy sensors. Optical damage can occur within the bulk of the material or at its surface but is more likely at the surface since there is a higher density of microscopic defects which can intensify the incident optical field. Optical components can also have anti-reflection coatings on them and so surface damage will often initiate here rather than at the surface of the bulk material. In any event, it is important to know the laser-induced damage threshold (LIDT) of a component since it can limit the overall operation of an optical system. The physical mechanisms that lead to laser-induced damage can be quite complicated and have dependencies on pulse duration and laser wavelength. Therefore, LIDT values are typically determined experimentally by evaluating the extent of damage induced at various intensity levels. The LIDT value for a material or component is defined at a specific wavelength or for a range of wavelengths. For CW lasers, this value is often given as a power density or intensity (in units of W/cm2), whereas for pulsed lasers the value is usually given as an energy density or fluence (in units of J/cm2).

Over 8,000 products in-stock! & FREE 2-Day shipping on all web orders!* Learn More FREE T-Shirt with orders $250+ Details

Over 8,000 products in-stock! & FREE 2-Day shipping on all web orders!* Learn More FREE T-Shirt with orders $250+ Details

Ultra-High Velocity

Ultra-High Velocity