Laser macroprocessing is defined as the machining of metal parts with thicknesses greater than a mm to produce large features with multi-mm dimensions. The process uses high power lasers with typical average powers ranging from a few hundred W to many kW. Key applications in macroprocessing are metal cutting, metal welding, and additive manufacturing of metals.

The laser cutting industry is expected to grow significantly over the next few years. Much of the growth is driven by the fact that the application space is constantly increasing. For example, the automotive industry is producing laser-cut and laser-welded car body parts, and the construction industry is using lasers to cut construction components. The plastics industry uses lasers to cut textiles and packaging materials. The biggest advantage to laser use is that any arbitrarily-shaped cut can be achieved, including 3D shapes, without the typical limitations of mechanical tools. Unlike mechanical processes, producing well-defined cutting edges is easily achievable because the laser process is non-contact and therefore wear-free. Hence, even the hardest or most abrasive materials can be processed without the need for tool replacements. Because the laser process is non-contact, no force or mechanical stress is applied to the processed part. This is especially important for the processing of brittle or soft materials as well as in high-speed cutting applications where material movement exceeds 100 m/s, e.g. when cutting paper. Additionally, laser systems reduce production time and tool costs because there is minimal set-up time and no need to produce individual tools when punching metal sheets.

In the metal cutting arena, lasers compete with plasma- and water jet cutting. However, the edge quality and ability to control power in lasers is superior to that of plasma cutters. Water jet has the best edge quality on very thick metal sheets and takes the lead when material thicknesses exceed 20 mm. With thinner materials, the greater flexibility of the laser is exploited. In the past, the CO2 laser was the workhorse for metal cutting. This was primarily due to its price advantage compared to solid-state lasers, e.g., the Nd:YAG laser, despite the fact that the latter delivers a better material absorbance. However, this has changed with the introduction of cost-effective disc and fiber lasers, causing CO2 lasers to be supplanted in many applications. Nonetheless, for organic materials like plastics or wood, there is no alternative to the CO2 laser because of the strong absorption at the FIR operational wavelength of 10.6 µm.

Laser welding is ubiquitous and has become the preferred technology in many industries over the past few years. It can be used to interconnect a wide variety of organic and inorganic materials. Production sectors dealing with mobility in the broadest sense, such as the automotive, shipbuilding, and aerospace industries are increasingly replacing bolted assemblies with welds. Laser welds provide permanent connections that save weight and reduce risks associated with nuts and bolts that can loosen or break over time. Welding is also commonly used in other applications including gas-tight welding of heart pacemakers, welding fine jewelry, and welding stainless steel in heat exchangers for white goods/appliances or in heater/cooler systems. Also, in contrast to traditional welding processes relying on electrical discharges, lasers can produce a minimal HAZ because it is possible to control the laser beam more precisely.

In laser metal welding, three major processes are currently in use. One involves conventional welding optics which have a rather short focal length, e.g., 100 to 200 mm. With the introduction of a filling wire, the joined parts are melted at a joint to allow both metals to mingle before cooling and becoming one solid part. It is important that there are no gaps in the joint between the parts to ensure the weld is effective. When using a filling wire, there are three components interacting. The two loose parts and the filling wire are melted in the focal spot and joined. The wire interacts with each of the materials and helps facilitate the connection between them. Another welding process, known as remote welding, uses a three-axis galvanometric scanning system with a long focal length, e.g., 0.8 to 1.5 m, that can be located far away from any obstructing parts. This is important for welding large parts like door panels where clamping fixtures are needed to ensure proper alignment but tend to interfere with the motion system used to position the laser. Such scanning systems allow for fast beam steering and generate many welding dots over a long distance in short time. Remote welding allows manufacturers to save valuable production time and achieve a higher throughput. Fiber lasers and disc lasers are typically used for laser welding and remote welding applications, while CO2 laser welding is preferred for certain applications because of the special weld seam characteristics provided by these lasers.

The third welding process, the welding of plastics, has different laser requirements. Diode lasers and CO2 lasers dominate this application process. CO2 laser wavelengths are absorbed by any plastic material regardless of whether the plastic is transparent or not. Diode laser wavelengths are only absorbed by colored plastics. This difference in absorbance leads to a welding strategy where one transparent part and one colored part can be joined by steering the laser beam through the transparent material onto the colored plastic to melt the colored plastic and join them together. One major use of laser welding in the automotive industry is for welding headlight and taillight assemblies. Laser welded housings for electronic components are also found in many applications.

Additive manufacturing is often a confusing topic because different technologies are combined in this application. The processes can involve melting materials and delivering them through a nozzle and depositing the melt layer by layer. This process is typically referred to as 3D printing. Processes that use a laser to melt or fuse powder are typically referred to as selective laser melting or laser sintering. Laser sintering can be used with different materials such as sand, polymers, or metal powder. Sintering sand is used for mold making in mold casting processes. Powder polymers are typically used for either mold making or to create components in rapid prototyping applications. Liquid polymers are used in laser stereolithography with a UV laser curing selected areas of the plastic to build a solid part. Model building for technical design and medical device applications are the main areas of interest for laser stereolithography processes. Metal powders were originally used with additive manufacturing processes to manufacture tools for molds in injection molding applications. However, metal powders are now also used in direct manufacturing of many functional parts, including parts for vehicles, bionic designs, and medical implants.

Today, large additive metal manufacturing machines can use up to four lasers at a time to produce either one large part or to produce multiple parts in parallel. While initially used to produce prototypes, additive manufacturing is increasingly being used by companies to efficiently produce complicated 3D structures. The benefit of this approach over traditional metal manufacturing techniques that selectively remove metal to produce a structure is the significant reduction in waste material.

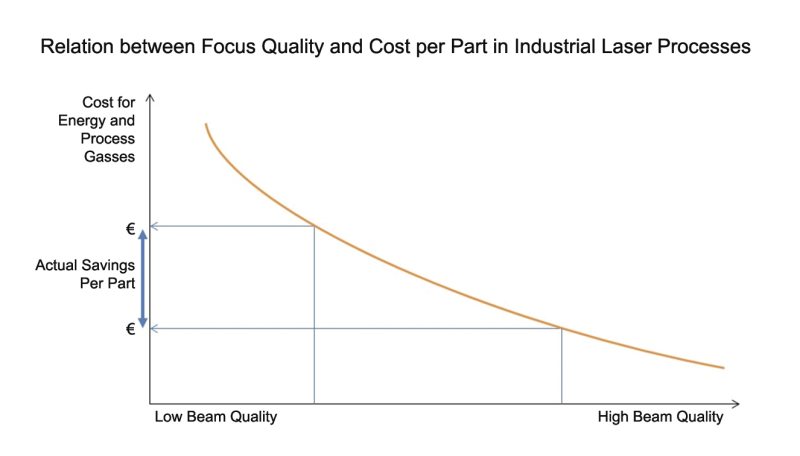

For macroprocessing applications, high power IR lasers with kW output powers are needed to perform metal cutting, welding and additive manufacturing processes. Most of these lasers are CW lasers, i.e., not pulsed, while some are quasi-CW where the laser is pulsed in ms timescales to increase the peak output power for a given average power. One particularly important parameter in these applications is the brightness of the laser beam as represented by its BPP (beam parameter product). BPP is the product of the beam diameter in mm and beam divergence in mrad (see

Laser Beam Spatial Profiles for details). Higher brightness levels (or lower BPP) are necessary for metal cutting applications, while metal welding applications require less brightness (or higher BPP). Figure 1 maps laser power versus BPP for various macroprocessing applications.

Over 8,000 products in-stock! & FREE 2-Day shipping on all web orders!* Learn More FREE T-Shirt with orders $250+ Details

Over 8,000 products in-stock! & FREE 2-Day shipping on all web orders!* Learn More FREE T-Shirt with orders $250+ Details

Ultra-High Velocity

Ultra-High Velocity