Ith represents the threshold current at which the device begins to lase. The efficiency of the laser in converting electrical power to light power is determined by the slope of the L.I. curve, denoted by the change in output power over the change in current (ΔP/ΔI). The inset schematically shows a broad area (100 µm wide stripe) laser diode emitting radiation from both its front and back mirror facets.

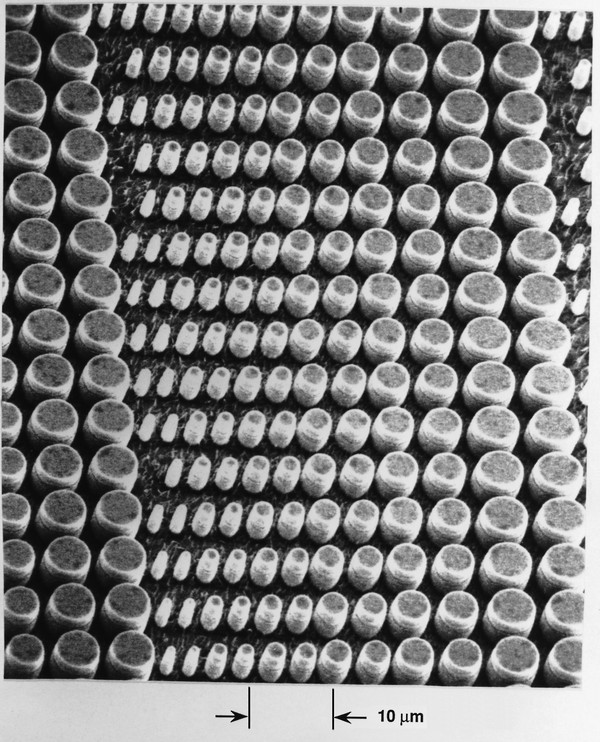

Threshold current is dependent on the quality of the semiconductor material from which the device is fabricated, and also the general design of the structure of the device waveguide. However, threshold current is also dependent on the size and area of the laser device. One laser diode could demonstrate a much higher threshold current than another device and yet be considered a much better laser. This is because the area of the device can be large. A laser that is wider or longer obviously requires more electrical power to reach the onset of laser action than a laser of a smaller area. As a result, when comparing the threshold current values of different devices, it is more appropriate to talk about threshold current density rather than threshold current. Threshold current density is denoted by the symbol Jth and is determined by dividing the experimentally obtained threshold current value Ith by the area of the laser. It is always desirable for a laser to have a low threshold current density value. Threshold current density is one of the parameters that is a direct indication of the quality of the semiconductor material from which the device is fabricated. In comparing the performance of various laser devices one must compare the threshold current density values rather than the threshold current values. In calculating the current density of the laser, it is necessary to accurately measure the area of the laser through which current is being injected. This is only possible in broad area type lasers with stripe widths on the order of 100 microns or more. In such cases, the area through which the current is flowing is very much the same as the area of the metallic contact of the laser. In cases of ridge lasers the width of the ridge is only a few microns while, due to current spreading, the actual width of the channel through which current is flowing could be considerably more. This makes it impractical to accurately determine current density values in cases of narrow stripe ridge lasers.

Just as it is desirable to reach laser action at as low a threshold current as possible, it is also desirable to get more and more light out of the device with the expenditure of as little current as possible. In other words, you would want to be able to increase the input current slowly and yet achieve rapid increase in the output light emission. A laser diode, which has a good rate of converting the input electric power to output light power, is obviously a device that is performing well. A direct measure of the ability of the device to do this is the slope of the L.I. curve. This slope is denoted as ΔP/ΔI and has the units of Watts per Amperes (W/A), or in the case of low-power lasers (mW/mA). ΔP/ΔI, which is the slope of the L.I. curve above the threshold current Ith, directly tells us how many Watts of power the laser outputs for every 1 Amp increase in its input current. Other important parameters are typically extracted from measurement of the ΔP/ΔI parameter. These include the External Differential Quantum Efficiency, Internal Quantum Efficiency, and Internal Loss parameters. Please refer to Newport's Application Notes for an in-depth discussion of these topics and the description of the experimental setups and calculation procedures needed to accurately determine the above-mentioned parameters.

In most applications, the ability of the laser diode to perform well at elevated temperatures is of great interest. This is especially of concern in the case of high-power laser diodes where the amount of power generated causes the device temperature to rise significantly. As a result, it is of utmost importance for the semiconductor crystal to be robust enough so as not to suffer from device deterioration at high temperatures. The characteristic temperature of the laser diode, which is commonly referred to as To (pronounced T-zero), is a measure of the temperature sensitivity of the device. Higher values of To imply that the threshold current density and the external differential quantum efficiency of the device increase less rapidly with increasing temperatures. This translates into the laser being more thermally stable. In order to measure the characteristic temperature of a laser diode it is necessary to experimentally measure the L.I. curve of a laser at various temperatures. The results are then tabulated and the To determined. Typically, people perform these measurements at temperatures ranging from 15 degrees Celsius up to about 80 degrees Celsius, and at 5 or 10-degree increments. Conventional AlGaAs lasers usually have To values above 120 degrees. Please refer to Newport's Application Note 1, Test and Characterization of Laser Diodes for more on this topic including the experimental techniques and calculation methods.

The series resistance of the laser diode is typically determined through calculating the derivative of the voltage versus injection current characteristic curve of the device. One way of doing this is to use a computer program to analytically determine the first derivative of the voltage versus current characteristic curve of the device that is obtained experimentally (more on this topic in Newport's Application Note 1). High series resistance values for a laser diode could be the result of low quality metal ohmic contacts deposited on the two sides of the device. As a result, measurement of the series resistance value can be a means of assessing the quality of the metallic contacts deposited on the laser.

As laser diodes have evolved over the past fifteen years, various structures have been developed with different characteristics. The first laser diodes used gain-guided structures, which are easy to fabricate, resulting in a reliable device at low manufacturing costs. This type of structure supports multiple modes, resulting in multiple spectral lines and astigmatism. Astigmatism is a condition in which the apparent focal points of the two axes do not coincide. It limits the ability to focus the laser beam to a small spot size (Figure 9) and complicates focusing the output beam to a sharp well-defined point.

Over 8,000 products in-stock! & FREE 2-Day shipping on all web orders!* Learn More FREE T-Shirt with orders $250+ Details

Over 8,000 products in-stock! & FREE 2-Day shipping on all web orders!* Learn More FREE T-Shirt with orders $250+ Details

Ultra-High Velocity

Ultra-High Velocity