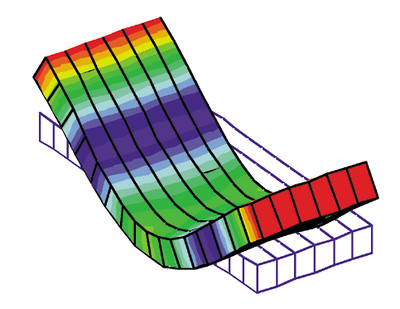

The example above shows the basic process used for determining the proper damper and location to eliminate the fundamental mode. Once the dampers are built into the table to attenuate this mode, the table is transformed from an RPR to an RS2000 with two dampers, or to RS4000 with six dampers.

Newport's tuned damping techniques allow the table construction to be tuned for specific applications.

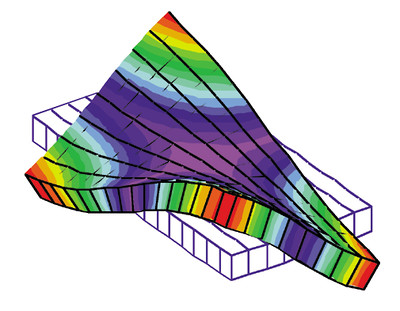

Doubled Tables: Modular Doubled Tables are multiple tables that are doubled together into complex monolithic structures that can exhibit very low frequency fundamental modes. When building these large structures, Newport assembles the doubled tables into their final configuration and tunes them as a monolithic system. Multiple dampers placed in selected locations (usually up to six dampers per section) can be used. Broadband techniques are very ineffective for such complex low frequency structures.

Large Table Loads: Tuned dampers are heavily damped, and their tuning is not “sharp” so that they stay effective in a frequency range centered around the tuning frequency. The performance is not significantly affected unless the equipment load exceeds 30% of the table weight. For example, an RS4000-48-12 weighs close to 1200 lbs - if the table load starts to exceed 360 lbs, the tuned dampers will be slightly less effective. In these cases, Newport will simulate the positional load and specially damp the table to the application requirement. Fortunately, most optical table experiments rarely exceed 30% of the table mass.

Special Shapes: Table structures with special shapes, cutouts, multiple levels and other custom features are modeled and tuned using the same process described above.

On-site tuning: Newport tuned mass dampers can be tuned or adjusted on-site. All it takes is to provide special removable corner pieces of the table.

- Eliminate fundamental mode resonances

- Offer much better vibration absorption at low frequencies

- Lighter weight does not mass load table construction

- Rugged bolted design with the damper mass supported by leaf steel springs is thermally stable and does not deteriorate in time

- Can be adjusted or re-tuned in the field (with special table corner covers providing accessibility)

- Less effective in reducing vibration amplitudes

- Does not work well for large tables with low frequency modes

- Heavy weight reduces table stiffness-to-weight ratio

- Rubber support pieces can degrade with time and change properties with temperature

[i] V.M. Ryaboy, Practical aspects of design, tuning and application of dynamic vibration absorbers, Proceedings of Meetings on Acoustics, 26, 065006 (2016); https://doi.org/10.1121/2.0000231 .

Over 8,000 products in-stock! & FREE 2-Day shipping on all web orders!* Learn More FREE T-Shirt with orders $250+ Details

Over 8,000 products in-stock! & FREE 2-Day shipping on all web orders!* Learn More FREE T-Shirt with orders $250+ Details

Ultra-High Velocity

Ultra-High Velocity